🇰🇷➡️🇬🇧 Translation: Hydrogen — The Core of Future Energy and Traditional Production Methods

Part 1: What is Hydrogen and Traditional Methods of Producing It

1. Hydrogen, The Core of Future Energy 🔑

Hydrogen (H) is the lightest and most abundant element, constituting over 90% of the universe, and is garnering attention as a core component of future energy systems. As an energy carrier, hydrogen is the ultimate eco-friendly energy source, emitting only water (H2O) and absolutely no carbon dioxide or other pollutants at the point of final use. Due to these characteristics, hydrogen is considered an essential solution for tackling climate change and realizing a carbon-neutral society.

Characteristics and Role of Hydrogen

- High Energy Density (by mass): Hydrogen has a very high energy density per unit of mass (approx. 120 MJ/kg), making it particularly useful for long-distance transport and large-scale mobility (ships, trucks, aviation). However, its energy density per unit of volume is low, necessitating high-pressure compression or liquefaction storage technologies.

- Diverse Applications: Beyond being a fuel for power generation or transportation, hydrogen is also widely used as an industrial feedstock (in refining, chemical, semiconductor, and steel industries). This range of application is expected to expand further.

- Energy Storage and Transport: Hydrogen plays a critical role in addressing the intermittency issue of renewable energy sources like solar and wind power. Excess electricity can be converted into hydrogen for storage or long-distance transportation, allowing it to become a medium for building a global energy network.

Hydrogen Color Coding: Hydrogen is categorized by its ‘color’ based on the production method to indicate its environmental impact.

- Gray Hydrogen: Produced by reforming fossil fuels (primarily natural gas), a process that emits carbon dioxide (CO2). This is currently the most common production method.

- Blue Hydrogen: Produced from fossil fuels, similar to Gray Hydrogen, but the resulting CO2 is captured and stored using Carbon Capture and Storage (CCS) technology to reduce carbon emissions.

- Green Hydrogen: Produced by splitting water through electrolysis using renewable energy, resulting in zero CO2 emissions during production. It is the cleanest form of hydrogen.

- Pink/Yellow Hydrogen: Refers to hydrogen produced via electrolysis using nuclear power (Pink) or grid electricity (Yellow), often classified as low-carbon or zero-carbon hydrogen.

2. Traditional Methods of Producing Hydrogen 🏭

The traditional methods that have so far dominated hydrogen production primarily use fossil fuels as a feedstock or involve conventional water electrolysis. These methods are the most advantageous in terms of technological stability and cost-effectiveness because they have been commercially used for a long time, but they carry the fundamental limitation of carbon emissions.

2.1. Steam Methane Reforming (SMR) — Gray Hydrogen

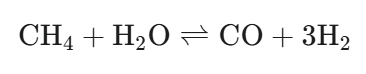

Steam Methane Reforming (SMR) is the most common and economical method, accounting for approximately 95% of the world’s current hydrogen production. It involves reacting methane (CH4), the main component of natural gas, with high-temperature steam at high temperatures (approx. 700ºC to 1000ºC) and high pressures (approx. 3MPa to 25MPa) to produce hydrogen and carbon monoxide (CO).

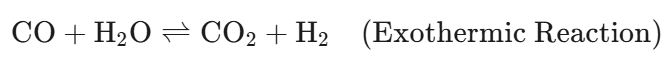

Subsequently, the generated CO undergoes the Water-Gas Shift Reaction (WGSR) to produce additional hydrogen and emit CO2.

- Pros: Low production cost, suitable for mass production, and the most commercially mature technology.

- Cons: A major source of carbon emissions, with approximately 9kg to 10kg of CO2 emitted per kilogram of hydrogen produced.

2.2. Coal Gasification

Coal gasification involves partially reacting coal with oxygen or air and steam at high temperature and pressure to create syngas (CO + H2), and then obtaining hydrogen through the Water-Gas Shift Reaction. It is widely used in countries heavily reliant on coal, such as China and India.

- Pros: Utilizes abundant coal resources.

- Cons: Emits more CO2 than SMR and also generates other environmental pollutants like particulate matter, thus referred to as Brown Hydrogen.

2.3. Reforming of Petroleum Byproducts like Naphtha

Hydrogen is produced by reforming naphtha or other petroleum byproducts generated in refining processes, similar to SMR. This method is primarily used when raw material supply is readily available within the relevant industrial complex.

2.4. Conventional Alkaline Electrolysis (AEC)

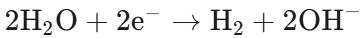

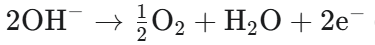

Electrolysis is the process of splitting water (H2O) into hydrogen (H2) and oxygen (O2) using electricity; if renewable energy is used, it results in Green Hydrogen. Traditional Alkaline Electrolysis (AEC) uses an aqueous solution of potassium hydroxide (KOH) or sodium hydroxide (NaOH) as the electrolyte and is the oldest and most stable commercially available electrolysis technology.

Cathode:

Anode:

Overall:

- Pros: Lower installation cost as it does not require expensive noble metal catalysts, and it offers high durability.

- Cons: Relatively lower efficiency and slow reaction speed limit its ability to respond quickly to the variability of renewable energy sources.

3. Limitations of Traditional Production Methods and Future Outlook 📈

The current hydrogen economy is mostly dependent on Gray Hydrogen from SMR, which inherently faces the issue of carbon emissions. As the transition to a carbon-neutral society accelerates, these traditional fossil fuel-based hydrogen production methods must shift to Blue Hydrogen (CCS applied) or be gradually replaced by Green Hydrogen production technologies.

- SMR’s Transitional Role: SMR will serve a transitional role as an economical, large-scale supply source to meet immediate hydrogen demand. However, the application of CCS technology to transition to Blue Hydrogen production is crucial to address the CO2 emission problem.

- The Great Shift to Green Hydrogen: In the long term, with the decline in renewable energy prices and advancements in electrolysis technology, Green Hydrogen is expected to become the most competitive clean hydrogen production method. This is driving a global push for the development of next-generation electrolysis technologies to overcome the limitations of traditional Alkaline Electrolysis. (This will be covered in detail in Part 2.)

The success of the hydrogen industry ultimately depends on securing price competitiveness and establishing a large-scale supply chain for clean hydrogen (Green/Blue Hydrogen), which will be achieved through innovative technological development that overcomes the limitations of traditional production methods.

Would you like me to find more information on the next-generation electrolysis technologies mentioned in Part 2?

Find Your Favorite Interesting thing!!에서 더 알아보기

구독을 신청하면 최신 게시물을 이메일로 받아볼 수 있습니다.